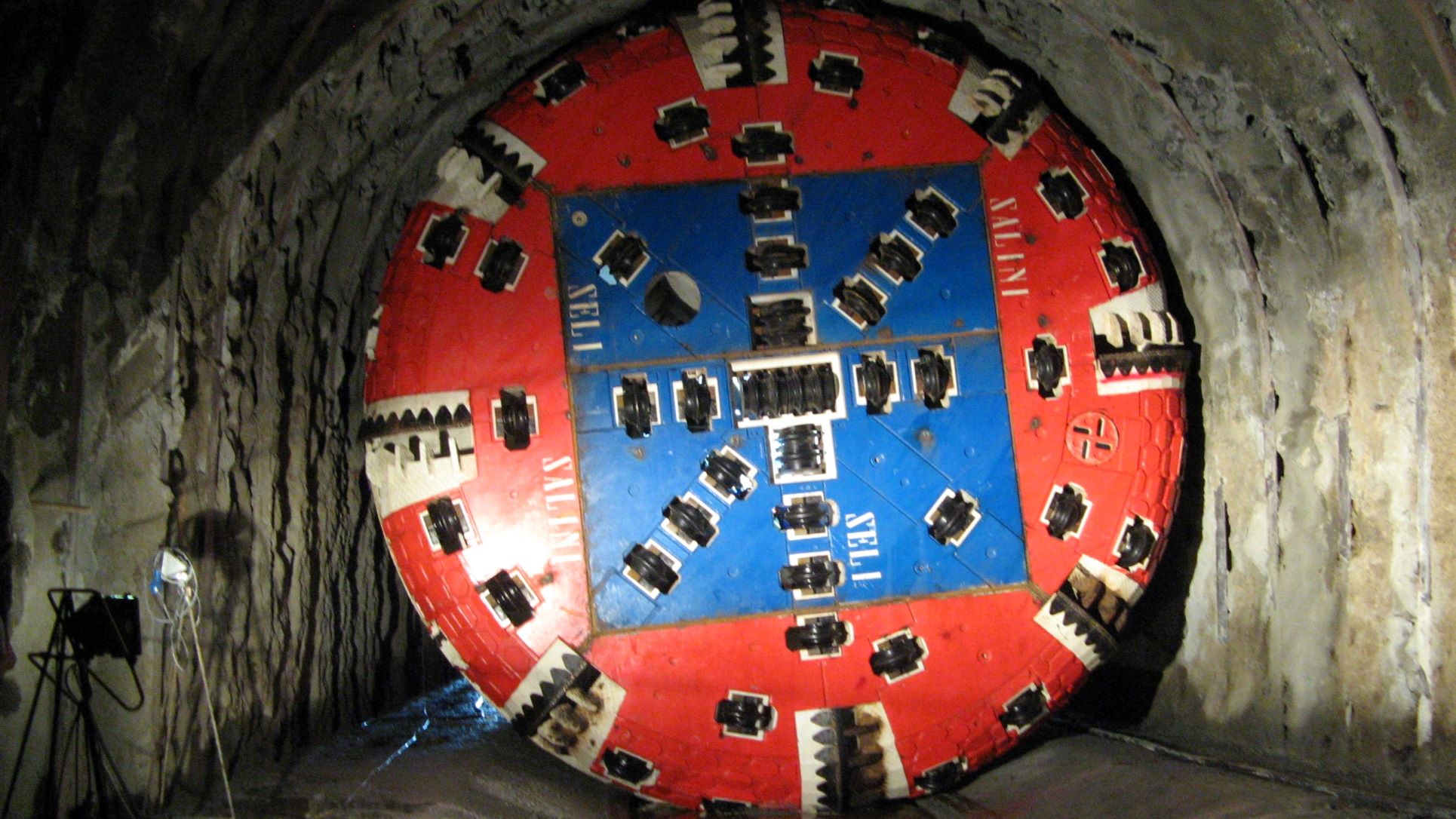

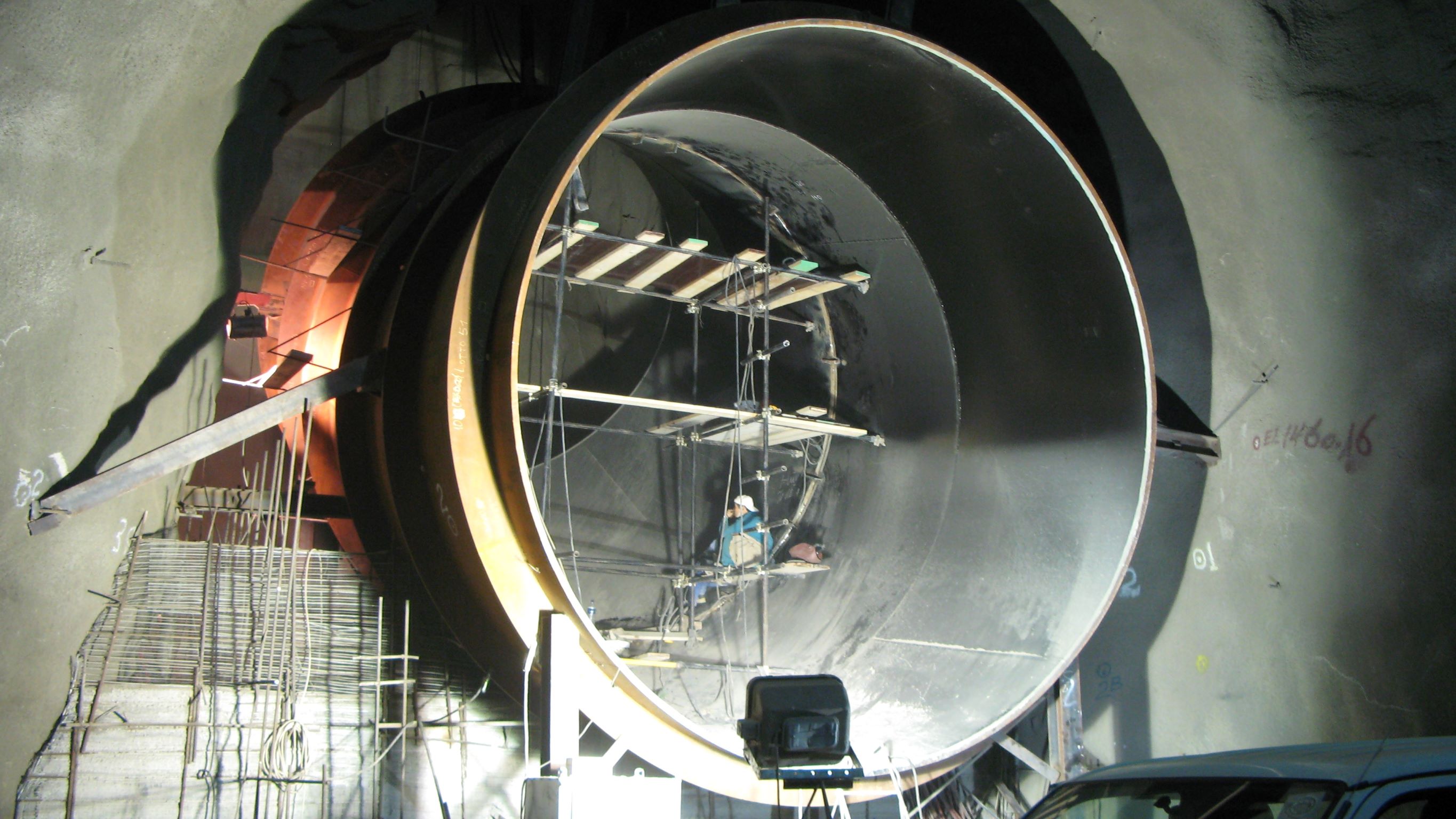

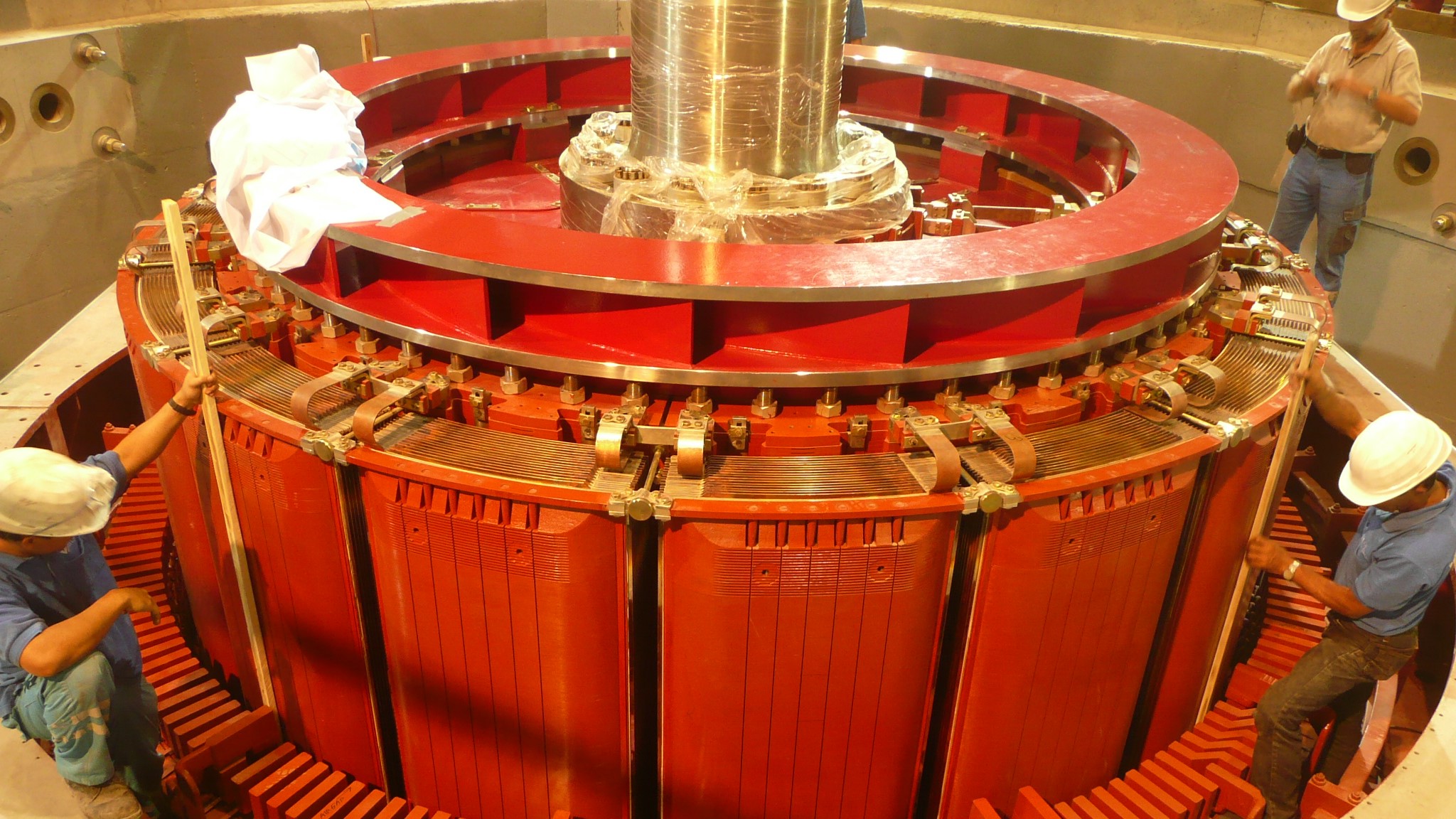

Engineering for hydropower plant and irrigation The Beles multi-purpose project is a hydropower plant located on Lake Tana, with an installed power of 460 MW, which diverts the flows from lake Tana into the Beles valley, allowing also the development of future irrigation schemes. The project was promoted by the Ethiopian Government to exploit the hydropower potential of Lake Tana and the Beles River, situated in the Blue Nile basin. The Plant, which minimizes the environmental impact because it is fully constructed underground, supplies Addis Abeba with energy at low cost, since 2010. The approach channel is located on the south-west side of lake Tana in order to convey the flows from the lake to the Intake structure and finally into a 12 km long headrace tunnel. The intake structure houses trash racks set to avoid passage of debris and floating material and has also four sliding gates installed to stop the flow and allow dewatering of the headrace tunnel, for inspection and maintenance activities. This 12 km long headrace tunnel connects the intake structure with the penstock shaft. The tunnel is almost entirely excavated with a TBM and lined with concrete precast elements. Given the great length of the waterways, a surge shaft is provided at the end of the headrace tunnel to mitigate the water hammer effects during the plant’s shut-downs or rapid flow variation caused by turbine manoeuvres. The shaft is a cylindrical structure 93 m in height, with a throttle located at the bottom. It is mostly excavated underground, adopting the rise boring technique, and only partially developed above ground. The steel penstock embedded in rock, leads the flow from the surge shaft to the powerhouse. It is subdivided into three stretches, namely the vertical penstock shaft 270 m in depth, the sub-horizontal high pressure headrace tunnel and a four branches manifold. The underground Powerhouse is located at a depth of about 300 m. It houses four Francis type generating units, the erection bay and the control building. The transformer cavern is located downstream and parallel to the powerhouse and contains the four step-up transformers. The Powerhouse and Transformer caverns are linked by the four bus-ducts and the access tunnels. A 275 m deep cable shaft connects the transformer cavern to the open air switchyard. The flow discharged by the Powerhouse, is conveyed into Jehana river through a 7 km long headrace tunnel, operating with a free flow regime. Three regulation weirs are constructed downstream of the Tailrace outlet in order to mitigate the effects of the additional discharge into the Jehana river. PLACE CLIENT YEAR The Beles project includes several outstanding examples of value engineering and design optimization, carried out throughout the entire design and construction period of the Project. One of the most evident aspects is the fast track approach adopted for the project implementation, under the EPC Contract framework, which allowed its completion, including all design phases (from Basic to Construction Design), investigations, and construction till the commissioning within 5 years. Since the beginning of the design activities, major efforts have been focused on accelerating all the activities on the critical path. The above fast track approach was generally adopted during implementation of the entire project. A second engineering challenge was the excavation of the headrace tunnel in lacustrine deposits, which required the provision of an EPB TBM machine and a special lining segment equipped with seals and anchor bolts. Lake Tana – Ethiopia

Beles Multi-purpose Project

Lake Tana – Ethiopia

Beles Multi-purpose Project

Lake Tana - Ethiopia

Salini Costruttori S.p.A.

2005 – 2011

Main Features

E = 1,840 GWh/y ) Examples of outstanding engineering challenges

As an example, the completion of the Underground Powerhouse was one of the most critical activities for the project implementation. Therefore, the excavation of the Powerhouse Adit, necessary to access the Powerhouse working area, started immediately, well in advance of the completion of the geological investigations and the selection of the exact location of the Powerhouse itself.

The route of the adit was then adjusted during excavation, when the location of the Powerhouse was eventually defined on the basis of the result of the geological investigations.

An optimization study to minimize the adit’s length was also carried out at the initial stage, taking into account the hydraulic constraints for the selection of portal elevation in order to avoid the risk of flooding, and transport constraints to allow the access with transformers in the cavern. Lake Tana – Ethiopia

Beles Multi-purpose Project

Engineering

ServicesFeasibility study

Basic design

Final design

Construction design

Consultancy during construction